Weighbridges in Mining: Accuracy Under Harsh Conditions

- Kanta King

- Oct 7, 2025

- 3 min read

Mining is one of the toughest industries out there. From scorching heat to heavy rainfall, from dust clouds to constant vibrations, everything in mining pushes machines and people to their limits. In such an unforgiving environment, accuracy and reliability are not just desirable—they’re absolutely essential.

One critical point where accuracy directly impacts productivity and profit is at the weighbridge. Whether it’s coal, iron ore, limestone, or any other mineral, every ton that enters or leaves a mine must be weighed. A few kilos lost in measurement here and there might not sound like much—but when scaled across hundreds of trucks every day, the financial loss can be massive. That’s why weighbridges play a crucial role in the mining sector, ensuring that no load goes unaccounted for and no resources are wasted.

Why Accuracy Matters in Mining?

Mining operations run on high volume and thin margins. A single truck can carry 30–100 tons of ore, and mines often dispatch hundreds of trucks daily. Imagine if each weighing had an error of even 50 kg. At first glance, it looks negligible. But multiplied across 500 trucks in a single day, that’s 25 tons of untracked material—enough to cause serious losses in revenue, planning, and taxation.

Accuracy isn’t just about money either. Mines are heavily regulated, and government authorities monitor every kilogram that comes out of the ground. Inaccurate weighing can lead to compliance issues, penalties, and even legal troubles. On top of that, mining companies need precise data to plan their operations, manage inventories, and maintain fair trade with clients.

The Harsh Realities of Mining Environments

Unlike a smooth factory floor, a mine is chaotic. Here are just some of the conditions weighbridges must withstand:

Extreme dust – Mining trucks constantly kick up clouds of dust, which can clog sensors and damage weighing systems.

Heavy vibration – Blasting, drilling, and constant truck movement create continuous vibrations that can affect weighing accuracy.

Temperature extremes – From burning hot afternoons to freezing nights, weighbridges face drastic shifts that test the durability of sensors and load cells.

Mud and waterlogging – During rainy seasons, mines can turn into swamps. Weighbridges must keep functioning even in these conditions.

Overloading pressure – Mining trucks often push their maximum carrying capacity, putting massive stress on weighbridge structures.

Only specially engineered weighbridges, designed for mining-grade toughness, can survive and stay accurate in such harsh realities.

How Modern Weighbridges Ensure Accuracy?

Over the years, weighbridge technology has evolved significantly to meet the challenges of mining. Here’s how modern solutions keep operations smooth:

High-strength load cells These are the heart of any weighbridge. Mining-grade load cells are built to handle heavy loads consistently, resist dust and water, and maintain accuracy over years of use.

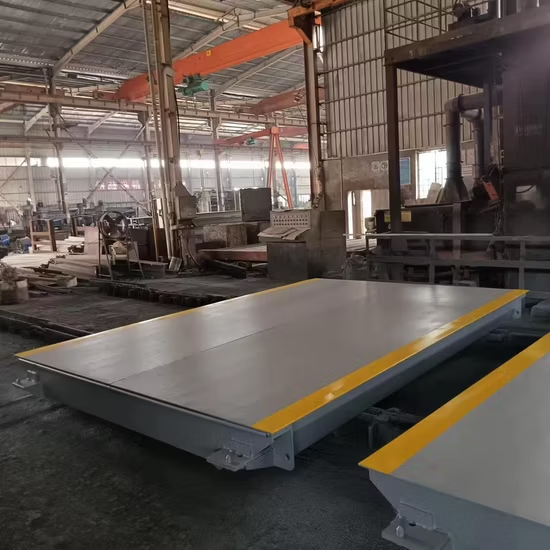

Robust steel structures The platform must endure constant heavy truck movement. Advanced designs with reinforced steel ensure the weighbridge doesn’t bend, crack, or lose calibration.

Protective housing and sealing Electronic components are shielded against dust, mud, and water. This prevents breakdowns in the middle of critical operations.

Digital calibration and sensors Smart weighbridges now come with digital load cells and automatic calibration, minimizing human error and ensuring consistent results.

Data integration In Industry 4.0-ready mines, weighbridges connect directly to software systems. This allows real-time monitoring, remote access, and automatic reporting for compliance and audits.

Lightning & surge protection Since mines are often in open areas, weighbridges are equipped with grounding and surge protection to keep systems safe from power spikes.

Building Reliability in Mining Weighbridges

Accuracy under harsh conditions isn’t just about installing a strong machine—it’s also about maintaining it properly. Mining operators need to:

Schedule regular calibration and servicing.

Use dust-resistant enclosures and covers.

Train operators to spot early warning signs of faults.

Integrate weighbridges with smart monitoring systems for alerts and reports.

When all these measures come together, a weighbridge becomes more than just a weighing tool—it becomes a critical pillar of mining operations.

Final Thoughts

Mining is tough—but weighbridges must be tougher. Accuracy under harsh conditions is not optional; it’s the backbone of efficiency, compliance, and profitability. With the right technology, smart maintenance, and a trusted partner like Kanta King, mining companies can turn challenges into opportunities, ensuring that every kilogram mined is measured with precision.

Because in mining, accuracy is more than measurement—it’s the measure of success.

KANTA KING

Website: https://www.kantaking.com/

Contact Us: +91.9560915555

Email: info@kantaking.com

Comments